Quonset Hut Homes – Are you looking for a new home but don’t want to break the bank? If so, then you should consider buying a Quonset hut home. Quonset hut homes are becoming increasingly popular due to their low cost and versatility.

Compare Steel Building Prices and save up to 30%!

Plus, they can be used for a variety of purposes, including residential, commercial, and agricultural use. So if you’re on the hunt for a new home that’s affordable and adaptable, then Quonset hut homes should be at the top of your list!

History

Quonset point is a small village in the town of North Kingstown, Rhode Island, United States. The village was named after the original Quonset huts, a type of prefabricated structure that was produced there during World War II by the Quonset Point Manufacturing Company.

The first Quonset huts were drafty military structures produced in 1941 and were used by the military for a variety of purposes, including as offices, barracks, and storage facilities. After the war, many of the Quonset huts were sold to civilians and have since been repurposed for a variety of uses, including homes, schools, and businesses.

Benefits of Quonset Hut Homes

Below are some of the key benefits that Quonset hut offers:

Quonset Hut Homes Are Economical

Quonset Hut homes are becoming an increasingly popular choice for those looking for an economical, yet stylish, home. Quonset Hut is a type of metal building that was originally used as military barracks during World War II.

Quonset huts are now commonly used as storage sheds, barns, and even homes. Quonset hut homes are especially popular among those who are looking for an alternative to traditional stick-built homes.

Prefabricated metal buildings are typically made from corrugated steel and are extremely strong and durable. Quonset hut homes can be built quickly and easily, and they are very affordable.

Arched metal buildings can be adapted to almost any climate, making them a great choice for those who want to live in a warm or cold climate.

Arched metal buildings are also energy efficient, thanks to the metal construction which helps to keep the home cool in the summer and warm in the winter.

Quonset hut homes are an excellent choice for those who are looking for an affordable, stylish, and energy-efficient home.

Quonset Huts Are Eco-Friendly

Quonset hut homes are becoming an increasingly popular choice for eco-conscious homeowners. Arched metal buildings are made from recycled materials, and they are highly energy efficient.

Arched metal buildings are also easy to construct, and they can be built without the use of heavy machinery. As a result, Quonset hut homes have a smaller carbon footprint than traditional homes.

Arched metal buildings are also more resilient than traditional homes, and they can withstand extreme weather conditions.

Quonset huts can be easily disassembled and relocated, making them an ideal choice for homeowners who want to reduce their environmental impact.

They’re Sturdy and Weather-Resistant

Quonset hut homes are an excellent choice for those who want a sturdy and weather-resistant home. Quonset huts are made from corrugated steel, and they can withstand high winds and heavy rains.

Quonset huts are also fire resistant, making them a great choice for those who live in areas prone to wildfires. Quonset hut homes are an excellent choice for those who want a durable and weather-resistant home.

They’re Customizable

Quonset hut homes are an excellent choice for those who want a customizable and stylish home. Quonset huts can be easily customized to suit the needs of any homeowner.

Quonset huts can be outfitted with a variety of features, including windows, doors, skylights, and more. Quonset huts can also be painted any color, making it easy to personalize your Quonset hut home.

Quonset hut homes are an excellent choice for those who are looking for an affordable, stylish, and customizable home.

They’re Easy to Transport and Install

Quonset hut homes are an excellent choice for those who want an easy-to-transport and install home.

Arched metal buildings can be disassembled and relocated, making them a great choice for those who want to move their home to a new location.

Arched metal buildings can also be installed on any type of foundation, making them a great choice for those who want to avoid the hassle and expense of traditional home construction.

Arched metal buildings are an excellent choice for those who want an easy-to-transport and install home.

Quonset hut homes are becoming an increasingly popular choice for those looking for an affordable, stylish, and easy-to-transport home.

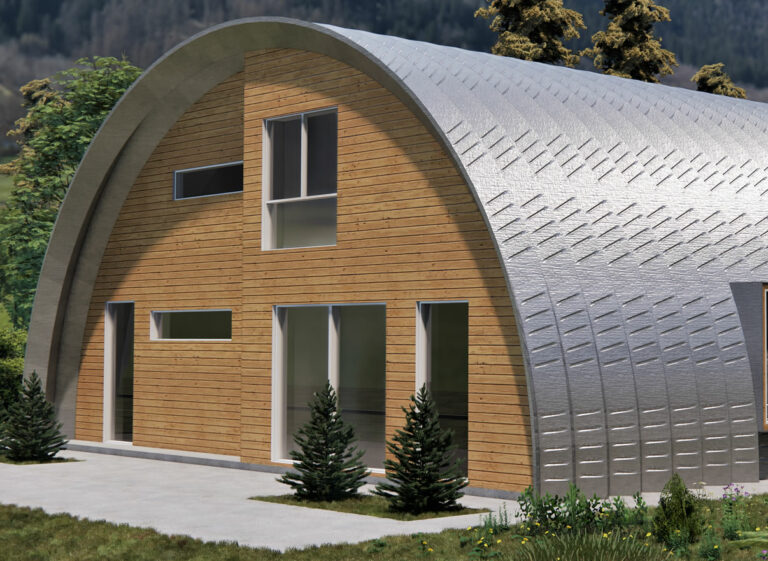

They’re Stylish and Modern

Quonset hut homes are an excellent choice for those who want a stylish and modern home. Arched metal buildings can be easily customized to suit the needs of any homeowner.

Arched metal buildings can be outfitted with a variety of features, including windows, doors, skylights, and more. Quonset huts can also be painted any color, making it easy to personalize your Quonset hut home.

A Quonset hut home is an excellent choice for those who are looking for a stylish and modern home.

Types of Quonset Hut Homes

Here are a few popular types of Arched metal buildings:

Prefabricated Quonset Hut Homes

Prefabricated Quonset homes are an excellent choice for those who want a quick and easy home.

Prefabricated Quonset homes are delivered to your site fully assembled, and they can be moved into place with a crane.

Do-It-Yourself Quonset Hut Homes

Do-It-Yourself Quonset homes are perfect for those who want a challenging and rewarding project.

Do-It-Yourself Quonset homes are a great way to save money on your home, and they can be a fun and rewarding project.

Custom Quonset Hut Homes

Custom Quonset homes are a popular choice for those who want a completely customized home. Custom Quonset homes are built to your specific specifications, and they can include any features that you want.

What Are the Uses of Quonset Hut Homes?

Quonset hut homes are an excellent choice for a variety of purposes. Here are a few popular uses for Quonset hut homes:

Homes

Quonset homes are becoming an increasingly popular choice for those looking for an affordable, durable, and easy-to-assemble living space.

A Quonset metal house is made from corrugated steel and is known for its arch-shaped roofs. Quonset hut homes can be adapted to any climate and are particularly popular in areas that experience severe weather conditions.

Modern Quonset hut homes can be built on any foundation, including concrete, gravel, or even sand. Quonset hut homes are an excellent choice for those looking for an alternative to traditional stick-built homes.

Quonset homes are an excellent choice for those who want affordable, stylish, and customizable living and storage purposes. It is a military style building with custom end walls, no interior structural supports and can be built in just a few days.

Offices

Quonset hut homes were once a popular choice for office buildings. These structures were easy and fast to construct, and they provided a cost-effective solution for businesses that needed extra space.

Quonset huts are now most commonly associated with military bases and storage facilities, but they can still be found in use as office buildings in some parts of the country.

Quonset hut office buildings typically have a very practical design, with basic amenities and little in the way of decorative features.

However, these structures can be surprisingly spacious and comfortable, and they often have a unique charm that more conventional office buildings lack. For businesses that are looking for unconventional office space, a Quonset hut may be the perfect solution.

Storage Buildings

Quonset hut homes are a great option for those who are looking for an alternative to traditional storage sheds. The metal hut has plenty of interior space and straight walls at the ends. Exterior walls are arched with a domed roof. Plenty of living space.

Quonset hut homes are made from Quonset huts, which are steel-framed structures that were originally used as military barracks.

Quonset hut homes can be adapted to any climate and are very easy to construct. Quonset hut homes are also very affordable, making them a great option for those on a budget and have alot of livable space to use.

Quonset hut homes are a great option for those who are looking for an alternative to traditional storage sheds. Quonset huts are steel-framed structures that were originally used as military barracks.

Quonset hut homes can be adapted to any climate and are very easy to construct. Quonset hut homes are also very affordable, making them a great option for those on a budget.

Quonset hut homes are a great option for those who are looking for an alternative to traditional storage sheds. Quonset huts are steel-framed structures that were originally used as military barracks.

Quonset hut homes can be adapted to any climate and are very easy to construct. Quonset hut homes are also very affordable, making them a great option for those on a budget.

Workshops

Quonset hut homes are becoming more popular as people look for alternative living spaces. Quonset huts are strong and durable, and they can be adapted to a variety of purposes.

They’re also relatively easy and affordable to build. As a result, Quonset hut homes are an attractive option for those who want to downsize or live off the grid. Plenty of room for mechanical equipment storage modern amenities.

Despite their popularity, Quonset huts are not without their challenges. One of the biggest challenges is finding a workshop that meets all your needs.

Quonset hut workshops come in a variety of sizes and styles, so it’s important to choose one that will fit your lifestyle and budget.

With so many options on the market, it can be difficult to know where to start. That’s why attending a workshop is a good idea.

At a workshop, you’ll have the opportunity to learn about the different types of Quonset hut homes and find the one that’s right for you.

Quonset hut homes are an excellent choice for workshops because they are spacious and well-ventilated and can have custom end walls.

Airplane Hangar

Quonset hut military structures are an excellent choice for airplane hangers because they offer a variety of benefits. They’re easy to construct, and they can be adapted to any climate. Quonset hut homes are also very affordable, making them a great option for those on a budget.

Cost to Build Quonset Hut Homes

The cost to build Quonset hut homes varies depending on the size and complexity of the home.

For a basic Quonset hut home, you can expect to pay between $15,000 and $20,000. For a more complex Quonset hut home, you can expect to pay between $30,000 and $40,000.

The cost to build Quonset homes varies depending on the size and complexity of the home.

How to Build Quonset Hut Homes

Building Quonset hut homes is a relatively simple process. Here are the steps that you need to take to build your Quonset home:

Choose a location for your Quonset hut home.

Before building you need to find the perfect location for your Quonset home. Once you have found the perfect location, you need to clear the area and level the ground.

If you are building on concrete, you need to make sure that the surface is level and smooth.

Excavate the area for your Quonset home.

Once you have chosen the location and prepared the area, you need to excavate the area for your Quonset house.

You will need to dig trenches for the foundation and the footings of your Quonset home is it also corrugated galvanized steel. Lightweight galvanized steel structures will protect your home from rust and corrosion.

Install the foundation and footings for your Quonset buildings. After excavating the area, you need to install the foundation and footings for your Quonset home.

Install the foundation for your Quonset hut home.

The foundation is the most important part of your Quonset hut insulation, and it needs to be installed correctly. If you are not familiar with foundation installation, it is best to hire a professional.

Assemble the Quonset hut kit according to the instructions.

After the foundation is installed, you can start assembling your Quonset hut kit. Quonset materials come with detailed instructions that are easy to follow.

Install the roofing and siding for your Quonset.

After the Quonset hut kit is assembled, you need to install the roofing and siding.

installing the roofing and siding is a relatively simple process.

Install the windows and doors for your Quonset house.

After the roofing and siding are installed, you need to install the windows and doors.

Finish the interior of your Quonset to your liking.

After the windows and doors are installed, you can finish the interior of your Quonset home to your liking. You can add walls, partitions, floors, ceilings, and fixtures to your Quonset home.

Finish the exterior of your Quonset home to your liking.

After the interior is finished, you can finish the exterior

What Are the Materials You Need to Build a Quonset Home?

The materials you need to build a Quonset home vary depending on the size and complexity of your home it also depends on the Quonset home interior.

For a basic Quonset home, you will need:

- A galvanized steel Quonset kits

- Concrete

- Bricks

- Plywood

- Lumber

- Windows

- Doors

If you are building a more complex Quonset hut house, you may

need:

- An architect

- A designer

- An engineer

- A contractor

- Quonset hut home builders

Quonset Hut Vs. Pole Barn

Pole barns are a type of agricultural building that is similar to Quonset hut homes. Pole barns are usually taller than Quonset hut homes and have different rooflines. Pole barns are also not as durable as Quonset hut homes and are not typically used as residences.

Quonset hut homes are a better option than pole barns if you are looking for a durable, long-lasting, and stylish home.

Quonset Hut Home Kits & Prices

There are many Quonset hut house kits on the market, and the prices vary depending on the size and complexity of the kit. For basic Quonset hut home kits, you can expect to pay between $5,000 and $10,000. For a more complex Quonset hut home kit, you can expect to pay between $20,000 and $50,000. Hiring a professional to help you build your Quonset hut home will add to the cost of the project.

How do I choose the right Quonset home?

When choosing a Quonset hut house, you need to consider the size, style, and complexity of your home. You also need to consider your budget and whether you want to hire a professional to help you build your home.

If you are unsure of which Quonset hut home is right for you, it is best to consult with a professional before making your final decision.

Garage Doors For Wood and Steel Buildings

The right garage door can add curb appeal and value to your home.

There are many different types of garage doors, and the type you choose will depend on the material of your Quonset hut home.

If your Quonset hut home is made of wood, you should choose a wood garage door. If your Quonset hut home is made of steel, you should choose a steel garage door.

There are many different styles of garage doors, and you should choose a style that compliments the look of your home.

You can also add windows to your garage door to let in natural light.

Internet Discussion of Quonset Hut Homes

Compare Steel Framed Prices and Save!

Simplify your research by letting us do the work for you.